The company does precision machining on materials such as steel, cast iron and aluminum, supplied both from the clients and from trusted suppliers.

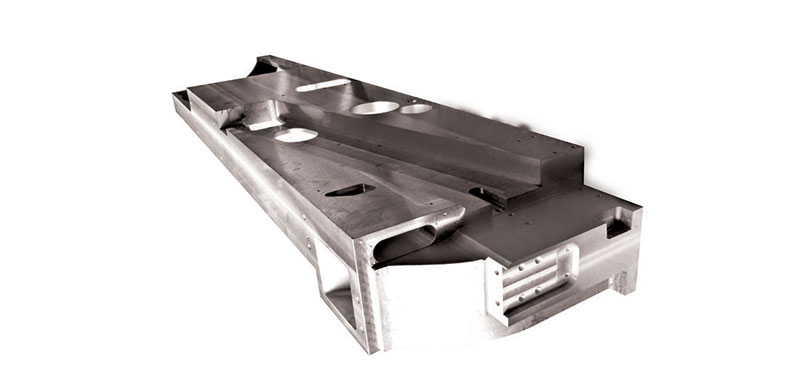

The main processes are milling and boring on horizontal, vertical and five-axis CNC machines for complex parts. We use milling-boring machines for bigger parts, usually on small production runs.

Dimensions for vertical machines are 6500x1000 while for the horizontal machines the dimensions are 1200x1200.

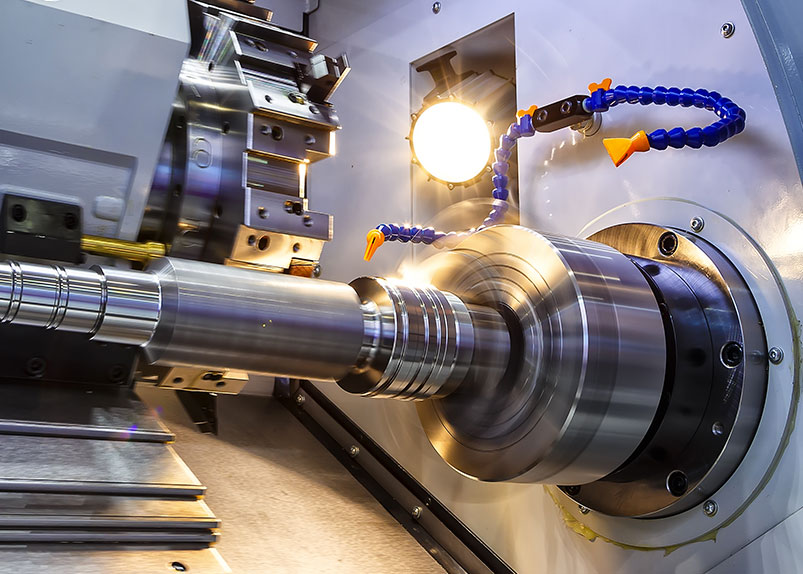

The turning department includes a manual lathe and two CNC turning machines that allow to work diameters up to 700 millimeters.

Surface grinding for slabs up to 600 millimeters, made of steel and aluminum.

For other processes such as cylindrical grinding, for heat-treatment and surface treatments, we rely on trusted external suppliers.

Furthermore, there is a small assembly department and a tool department that sets up tools for all the machines.